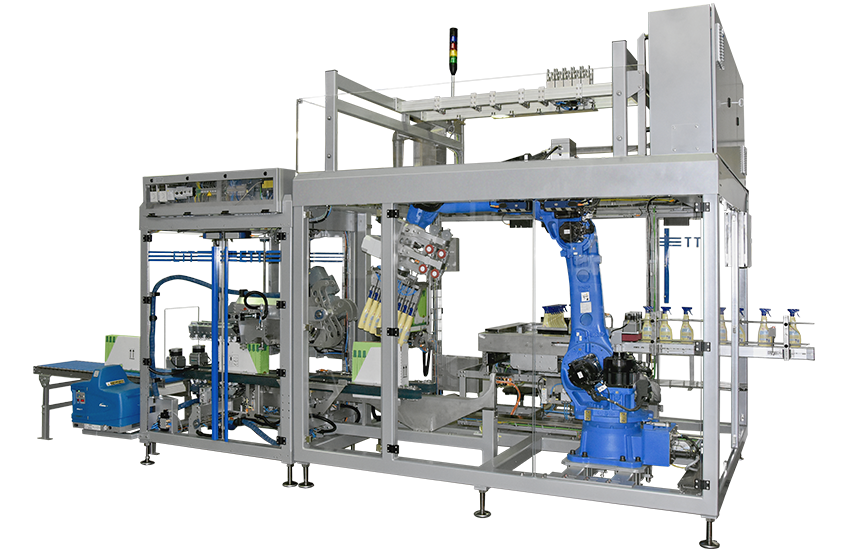

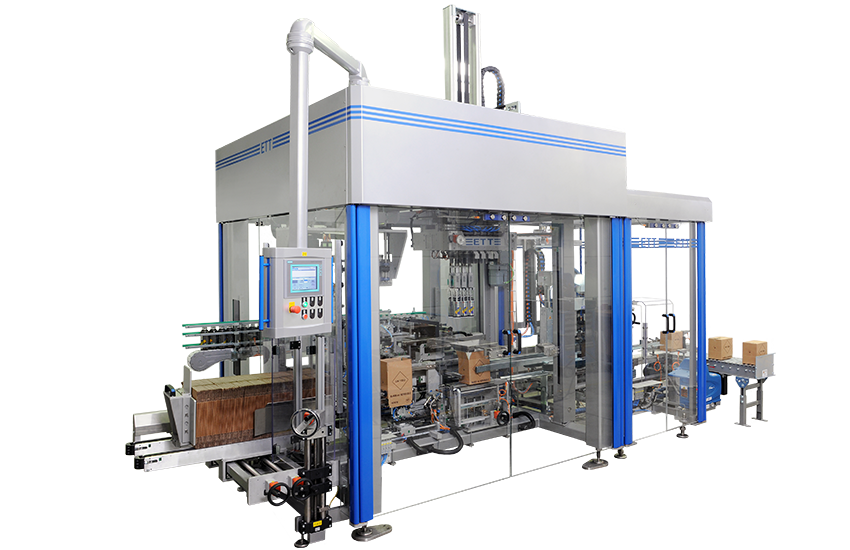

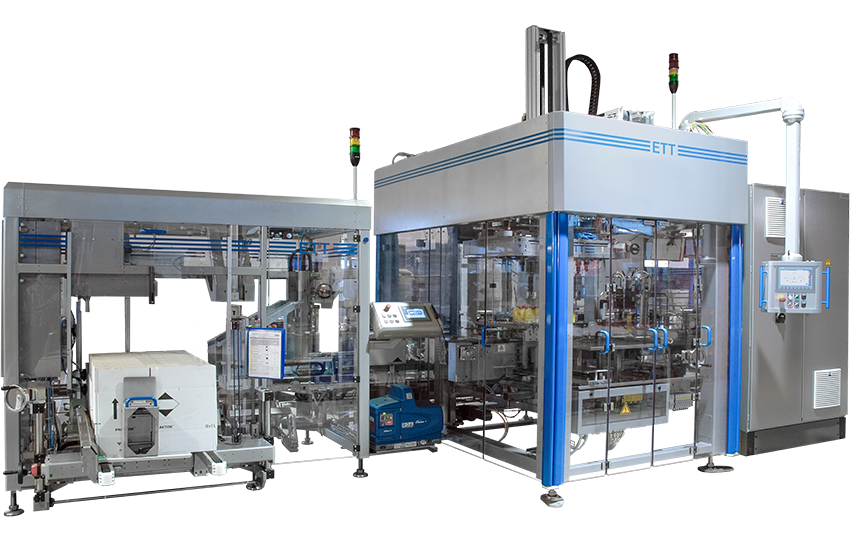

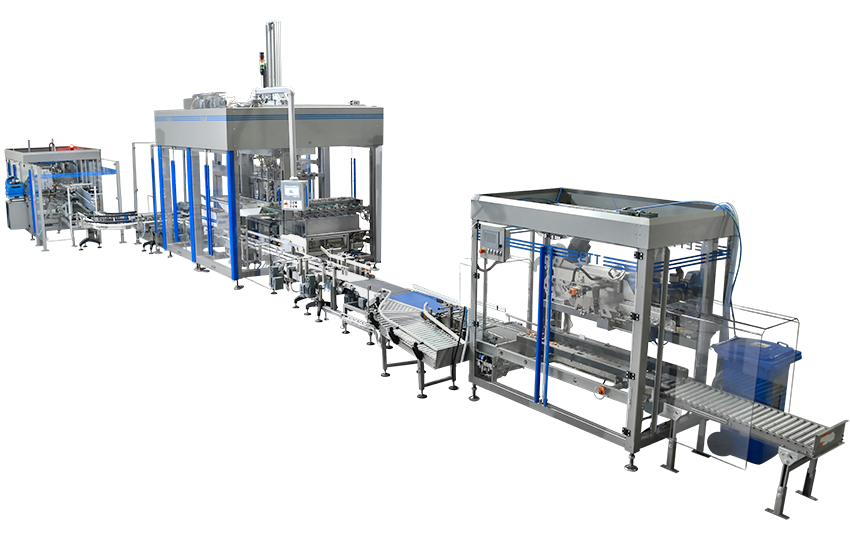

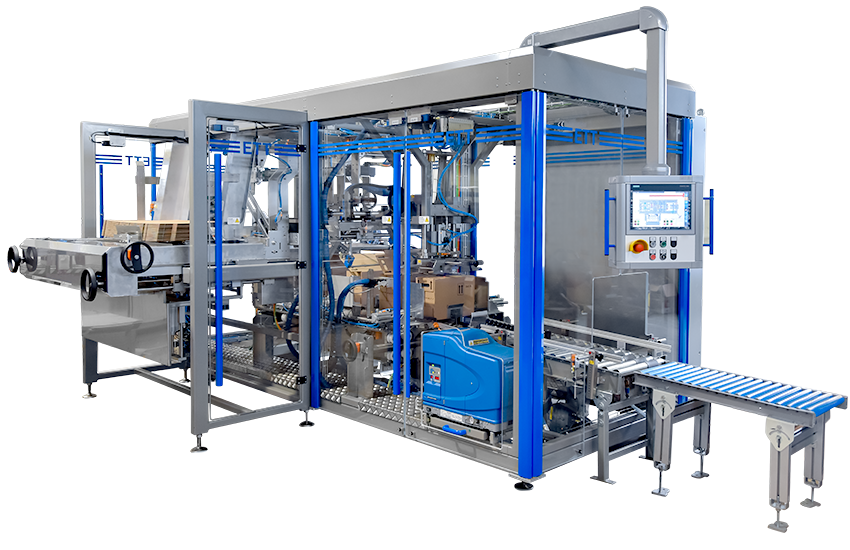

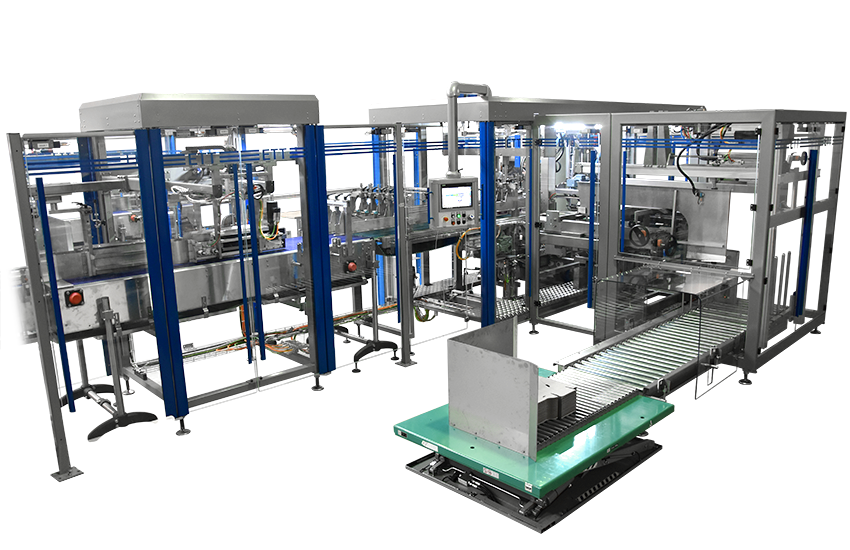

Roboblock

Designed as a complete solution, the Roboblock consists of a compact machine chassis with an integrated robot-based pick & place packing module and a case forming and sealing module. Thanks to its very low space requirements, high versatility and favourable price it is the perfect system for your entry into the world of automation.

Speed: up to 7 or 12 cases per min.

Sealing methods: Self-adhesive tape or hot glue

Your benefits: optionally available with fully automatic changeover function